Incinerator Installations

Chuwastar

Chuwastar is a Japanese, Incineration System that has in-built advanced technical features. The key advantage of this product is it gives a SMOKELESS Incineration. For a complete combustion, the Chuwastar uses controlled gasification technology.

Key Highlights

- Very fast Incineration (60-minute cycle)

- High heat combustion

- Incineration without emitting smoke (Smokeless)

- Assorted types of waste can be incinerated at once

- Top-level durability – The main structure and cyclone dust collector is made using Graded SS400

- Long-term usage and durability are attained by applying a chemical coat comprising iron and aluminum. This special formula of chemical gives added protection against acidity and heat.

- Heat gathering system.

- Hot water utilization.

Features

- Water Cooled Structure

- The main body of furnace is fully covered with water jacket system.

- Therefore even plastic, which produce a lot of heat, can be incinerated easily.

- By water – cooled structure, CHUWASTAR’s durability is outstanding.

- Made by steel board

- The main body of furnace and the cyclone dust collector are made by steel board, SS – 400.

- Therefore if damaged, it can be easily repaired.

- Made by Aluminum processing

- Cyclone and exhaust duct are made by steel board, and those are covered with alloy of iron and aluminum.

- By this process, those parts have excellent durability against acid and heat.

- Fireproof material

- Fire proof material is used for hearth, an injection door and the ash outlet door.

- Forced air supply method

- The air is supplied compulsory to furnace by high pressure turbofan.

- The necessary oxygen is supplied with stability, and it enable the complete and smokeless incineration.

- Air Supply nozzel system

- A lot of air supply nozzles located on efficient positions ensure the enough oxygen.

- It enables complete combustion and smokeless incineration.

- Water – cooled pipe for prevention of backfire

- A water – cooled pipe is established for prevention of backfire in furnace.

- This device ensures safty, and anyone can use the incinerator without precial skill.

- Ejector device

- It is a device to keep minus number pressure inside the furnace and increase the efficiency of dust collection.

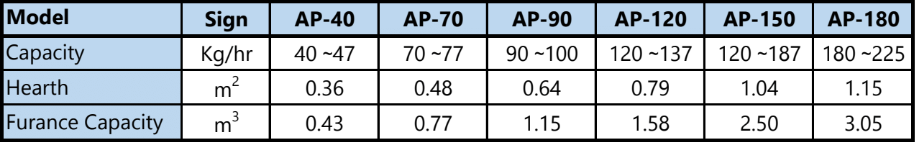

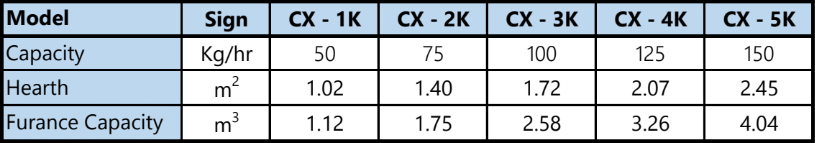

Standard Specification

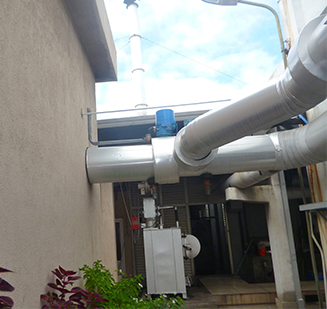

Incinerator Installations

Asiri Central Hospital

Fuego IMS 600 Medical waste incinerator machine.

This was installed in 2019.

Capacity – 50 kg/hr

Fuel Type – Kerosene

District General Hospital – Ambilipitiya

Brand & Model – FUEGO IMS 500

Commissioned in 2017

Capacity – 40 kg/hr

Waste type – Clinical waste

Amaria Hotel – Havodda Maldives

Brand & Model – FUEGO IMS 500

Capacity – 40 kg/hr

This incinerator is used for discarded plastics and other municipal waste

The Embassy of Japan

Brand & Model – FUEGO IMS 75

Fuel type – Kerosene oil

Capacity – 10 kg/hr

Used for – Majorly for paper related waste

The Korean ambassador’s residence

This machine is primarily used for the municipal and garden waste within the premises.

Capacity – 20 kg/hr

The Embassy of Republic of France

Installation happened in 2019.

Since this machine exhibiting its true capabilities, embassy staff is truly amazed with what they are getting in return. A true champion in its capacity!

Destruction Capacity – 10 kg/hr

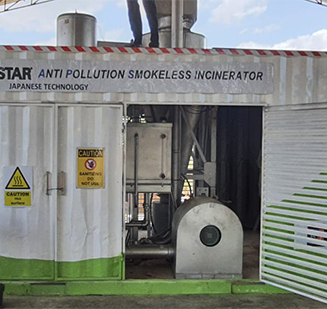

GFC Waste Management Pvt Ltd

Band & Model – CHUWASTAR CX 1K

This is the prime example for Japanese high quality incineration capabilities. Smokeless incineration is its motto and proves every time.

Shook Sri Lanka by writing history books offering its service to the commercial medical waste incineration.

Capacity – 60kg/hr

Hrischandra Mills – Matara

This Fuego font runner was able to demolish their acute plastic related waste disposing problem.

Whole organization was pleased with its performances and its economical operational costs.

Capacity – 20 kg/hr

MDK Foods – Horana

All of their Food manufacturing related waste are incinerated in our environmentally friendly machine.

Capacity – 40 kg/hr

Pulmudai Base Hospital

This machine was installed in the North Eastern corner of the country, through MOH funding.

Capacity – 40 kg/hr

Orrivaru – Maldives

Brand & Model – FUEGO IMS 400

Capacity – 30 Kg/hr

This incinerator is used for general waste.

Capella – Maldives

Brand & Model – FUEGO IMS 600

Capacity – 50 Kg/hr

This incinerator is used for general waste.

ICL – Maharaja

Brand & Model – FUEGO IMS 800

Capacity – 60 Kg/hr.

This incinerator is used for wood, textile & paper.

Divisional Hospital – Mawadiwembu

Brand & Model – FUEGO IMS 200

Capacity – 20 Kg/hr.

This incinerator is used for medical waste.

Upper Kothmale Hydro Project

Brand & Model – FUEGO IMS 75

Capacity – 10 Kg/hr

Incinerator Installations

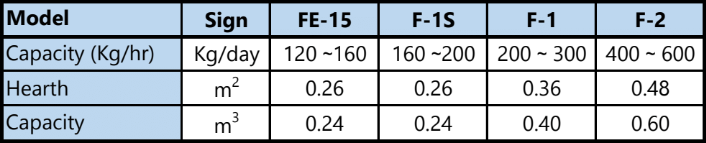

GAIA Automated Food Waste Composter

The GAIA Automated Food Waste Converter is made by using industry-proven top-level South Korean technology. This ultra-modern converter of food waste is renowned for being environmentally friendly. The GAIA Automated Food Waste Convertershave been installed at London Heathrow International Airport, London Gatwick International Airport, Burj Khalifa U.A.E., Carrefour and Leclerc Hypermarkets in France and Laneways in the city of Melbourne.

Key Highlights

- One-touch control fully automated design

- Volume ranges from 20 kg / day up to 200 tons / day

- Able to convert organic and food waste into animal feed and fertiliser

- Simple to use straightforward portable design

- Reduction in volume up to 85-90%

- Proven, low maintenance, trouble-free design

- Odour and rodent-free

- Do not require bioagents, chemicals or additives

- Uses less space and power requirement

- No special skilled labour is required to be stationed to operate the machine

- The machine can take various types of contaminated and packaged food waste.

- This device is ideal to be used at Food Production Facilities, Hotels, Restaurant, Commercial Kitchens, Supermarkets, Hospitals and Military Basements.

Incinerator Installations

SANGIR KLEAN CHUTE

SANGIR Garbage and Linen Chutes are manufactured in India to match world standards in the industry. The raw materials used for the manufacture of garbage and linen chutes are pre-tested before use and of the highest quality. State-of-the-art, modern manufacturing methods put into use by professionals have been employed by SANGIR in keeping with the best manufacturing practices. The garbage and linen chutes are extensively used in residential establishments and high-rise apartment complexes to collect all garbage at one place.

Key Highlights

- Long-lasting construction achieved using premium material and equipment (stainless steel)

- Low Impact Double Slope Throat Design

- Advanced Intake Door Design with double-walled doors and clean stainless steel finish.

- Auto Closing Fire Fighting Doors

- Automatic Fire Sprinklers

- Clean & Odour Free operation with a built-in sanitising system

- Advanced ventilation system